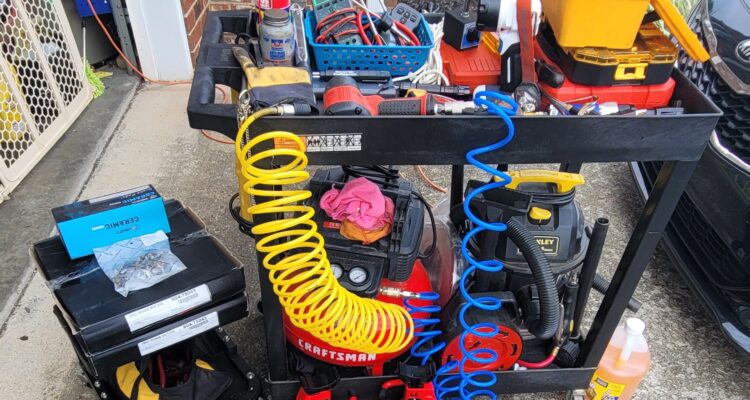

I did my daughter’s front brakes. Figured I would document my process in case it could help others. Sorry for the audio and background noise, etc… in the video. This was a last minute decision to document the process so I didn’t bother setting up my fancy recording apparatus or practicing, just wanted to get er done. I figured someone may find it helpful. It’s pretty basic stuff but i do list torque specs and things like that and probably call things the wrong name LOL so… take it easy on me haha. you will need: brake and rotor ‘kit’ for the specific vehicle safety glasses, ear plugs, gloves, etc… cardboard, etc… to contain the mess under the work area, and for kneeling on, etc… jack, jackstands, wheel chocks torque wrench with 20~90 ft⋅lbf range 14mm (~25 ft⋅lbf), 19mm (~77 ft⋅lbf), and 21mm (~76 ft⋅lbf) sockets, wrenches, etc… rags, brake cleaner, foam swabs, anti-seize compound, wire brush, etc… method to compress dual piston systems if you can’t manually compress them better with: brake fluid moisture tester, pneumatic impact and ratchet, air blowing nozzle, low-profile mechanics stool with tool tray, extra brake fluid, fluid syphon pump (just in case), etc… Here is an AI generated summary of the video: The Ultimate Guide to Replacing and Reconditioning Brakes on a 2019 Lexus RX 350 Brakes are one of the most important parts of your vehicle. They keep you safe on the road by stopping your car when you need them. Over time, brakes wear out, and replacing or fixing them becomes necessary. Doing your own brake work might seem hard at first, but with the right steps and tools, you can do it confidently. This guide takes you through each step to inspect, disassemble, clean, and reassemble the brake system on a 2019 Lexus RX 350. Understanding the Brake System of a 2019 Lexus RX 350 Overview of Brake Components Every brake system has key parts that work together for safe stopping. The calipers squeeze the brake pads against the rotors to slow down the wheel. The brake pads press against the rotors to create friction. The rotors are metal discs attached to the wheels. Brake pins help the calipers slide smoothly. Sensors alert you when pads are worn out, and hydraulic fluid transfers force from the brake pedal to the calipers. Each piece plays a vital role in braking performance. Unique Aspects of Lexus RX 350 Brakes Lexus RX 350 uses specialized features like ABS sensors and wear indicators. The caliper pins are designed for smooth movement with correct lubrication. OEM specs recommend brake service intervals to keep braking sharp. Knowing these details helps you understand what to expect and how to maintain your brakes properly. Preparing for Brake Service Tools and Equipment Needed Gather these tools before starting: Hydraulic jack and jack stands Impact wrench and socket set (preferably 21mm for lug nuts) Torque wrench to tighten bolts properly Screwdrivers, brushes, and clean rags Non-chlorinated brake cleaner Plastic tools and pick sets High-temp brake grease and antiseize compound Gloves, safety glasses, and a respirator if needed Safety Precautions and Best Practices Always work on a flat, stable surface. Use wheel chocks on the opposite tires and engage the parking brake. Support the vehicle with sturdy jack stands—never rely solely on the jack. Wear safety gear to protect your eyes and hands, especially when handling brake chemicals. Working safely keeps accidents at bay and ensures your tools work effectively. Step-by-Step Brake Inspection and Fluid Testing Checking Brake Fluid for Moisture Content Start by inspecting the brake fluid reservoir. Use a moisture tester to see if the fluid has absorbed water. If the moisture level is high, it’s time to drain and replace the fluid. Also, check the filter basket inside the reservoir. Carefully remove it with a hooked tool, clean, and inspect it. Visually assess the fluid and decide if a flush is needed. Fresh brake fluid helps maintain optimal braking and prevents damage. Assessing Brake Pad and Rotor Condition Look for uneven pad wear or deep grooves on the rotors. Small cracks or scoring may indicate the need for rotor replacement. Measure the thickness of the pads—if they’re close to the minimum thickness, swap them out. Also, inspect caliper seals and pistons for leaks or rust. Catching these issues early keeps your brakes working smoothly. Disassembling the Brake System Lifting and Securing the Vehicle Begin by parking your car on a flat surface. Chalk the back wheels to prevent movement. Use a hydraulic jack at the proper lift points on the Lexus RX 350—these are marked under the vehicle. Place jack stands under sturdy frame points and lower the car onto them. Always double-check stability before crawling underneath. Removing the Wheels Loosen lug nuts with an impact wrench. Keep them in a safe place and remove the wheels. Set them aside where they won’t get damaged. Now your brake system is exposed and ready for the next steps. Detaching the Calipers and Rotors Remove the two caliper pins (usually 14mm). Once those are out, carefully lift or support the caliper with a bungee cord or wire—never let it hang on the brake hose. Remove the brake pads from the caliper. Next, unbolt the rotor from the hub, taking care not to damage the wheel hub surface. Wiggling and gentle tapping may be needed for stuck rotors. Disassembling Calipers and Pads Take pictures or videos during disassembly to remember the order of parts. Carefully remove slide pins and clips, cleaning them as you go. Examine the pistons and seals for damage. Clean the caliper parts thoroughly to prepare them for reconditioning or replacement. Cleaning and Reconditioning Brake Components Brake Part Cleaning and Airborne Particles Safety Spray non-chlorinated brake cleaner inside the calipers, and on rotors and pins. Use a spray and a rag to wipe away dirt and brake dust. Protect your eyes and lungs by wearing safety glasses and gloves. Spraying at an angle minimizes dust becoming airborne. Always work in a ventilated space. Inspections and Damage Checks Inspect each part carefully. Look for scratches, corrosion, or uneven wear. Replace any worn or damaged parts, such as seals or